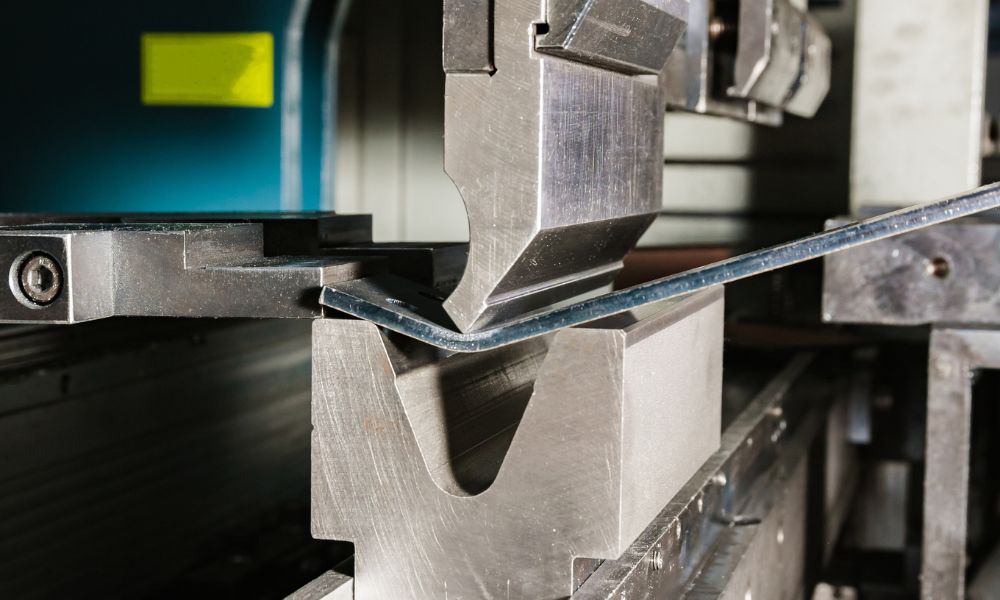

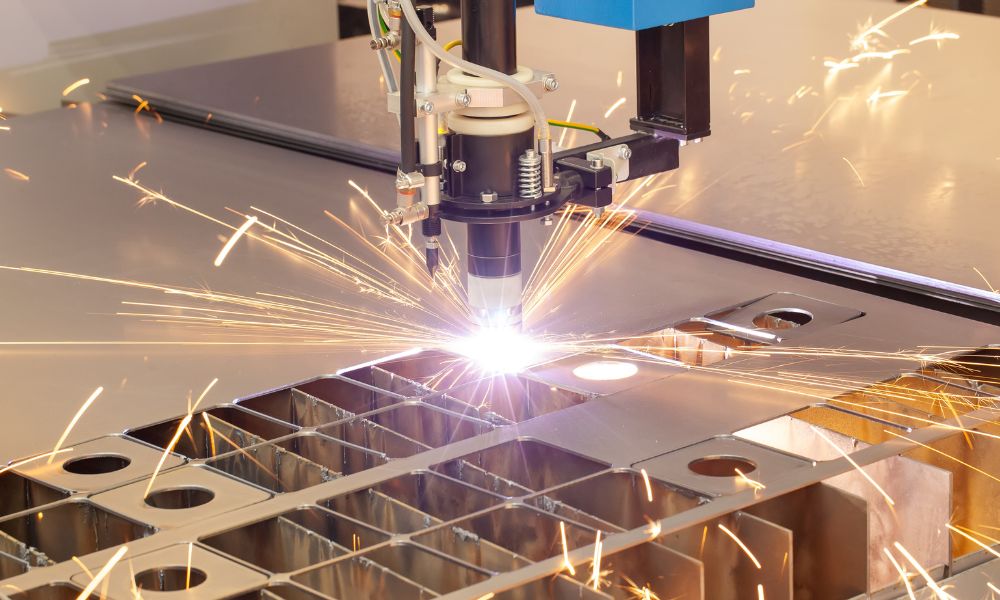

What To Know Before Buying Used Metalworking Equipment

There’s nothing wrong with purchasing used metalworking machinery—if there’s nothing wrong with the machine, the dealer that sells it, or the availability of parts and service. These are the major considerations included in what to know before buying used metalworking equipment. (more…)