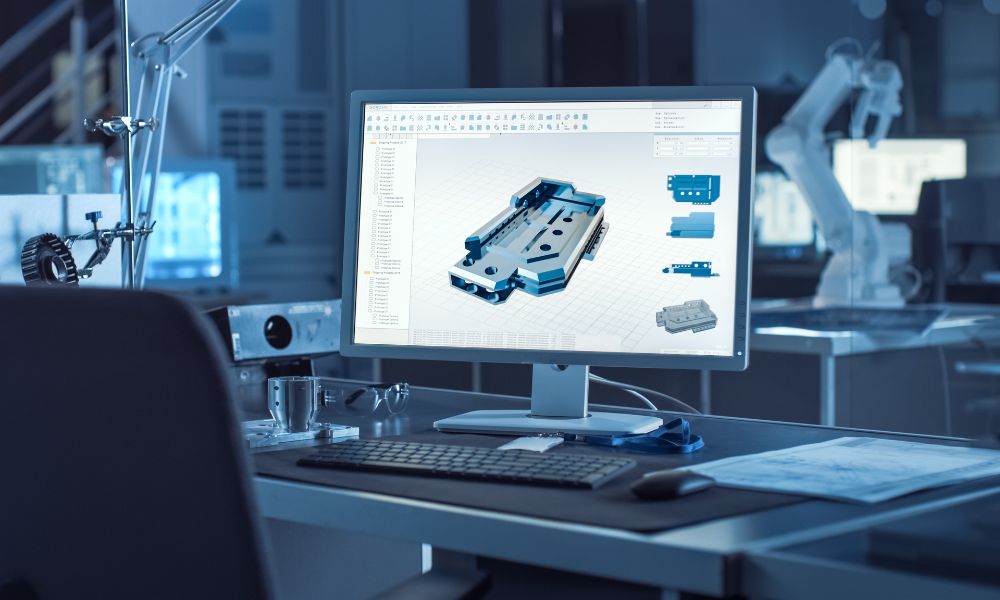

3 Uses for CAD/CAM Software in Fabrication

CAD/CAM software is an essential tool for modern metal fabrication, providing industry professionals with powerful and efficient design capabilities. With CAD/CAM software, designers can draw up complex plans and programs that can be accurately implemented in the manufacturing process. Let’s explore three uses of CAD/CAM software in fabrication: product design and development, production planning and optimization, and machine control. Product Design & Development CAD/CAM software provides designers with powerful tools to create detailed models of components and assemblies. By combining 3D [...]