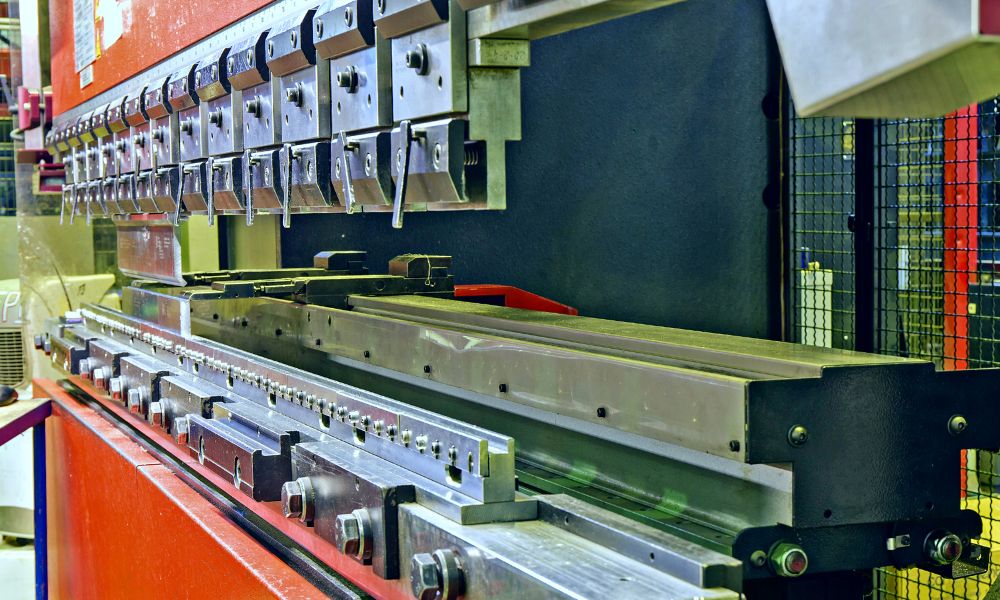

Press Brakes

Reasons Why Press Brake Tooling Is Important

Press brake tooling plays a pivotal role in any metalworking shop. It is the cornerstone of precision sheet metal fabrication, providing the necessary force and shape to bend and form sheet metal into desired configurations. Consider several reasons why press brake tooling is important, reviewing the materials used and essential punches and dies as well as solutions for long sheet metal. What Is Press Brake Tooling Press brake tooling refers to specific interchangeable parts used in a press brake to bend [...]