Cutting Machines Found in a Metal Fabrication Shop

Metal fabrication shops are always buzzing with people. You’ll rarely see workers sitting around discussing Monday night’s football game because they have too many projects on the docket. Instead of chatting, fabricators spend their days behind high-tech devices. Here are some of the most common cutting machines found in a metal fabrication shop. Anyone having trouble finding an employee should check behind these devices; the employee may just be engrossed in a project.

Plasma Cutter

Plasma cutting systems are excellent for breaking through thick material. Mac-Tech sells state-of-the-art plasma cutters that are perfect for heavy-duty jobs that can’t be completed by hand. For example, the Ermaksan EPL can cut through materials as thick as 1 ½ inches. In addition, the device can produce 2-3 times more parts per hour. Productivity will increase, meaning shops can take on more projects.

Laser Tube Cutting Machines

Not all cutting machines are created equally. Some pieces of equipment break through flat sheet metal, while others cut through unique shapes. Laser tube cutting machines are the perfect example of a device fit for a special project. It would be nearly impossible to use a plasma cutter on a circular item because the device does not bend that way. Supervisors should invest in laser tube cutting machines to make everyone’s lives easier.

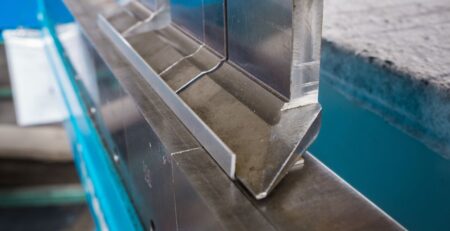

Shears

Sometimes, you don’t need high-tech machines to make precise cuts. If you want to get through a job quickly, think about using metal shears. Shears may not be as accurate as plasma cutting systems, but they require less setup time and minimize the likelihood of injury. Employers can check out our selection of shearing machines today. The Ermak HVR is incredibly user-friendly and includes emergency stops in case something goes wrong. There are many advantages to having this device at your establishment.

Workers would have to do everything by hand without these cutting machines found in a metal fabrication shop. Old school methods slow down production and increase the likelihood of workplace accidents. There’s no reason employers shouldn’t get these devices for their business. Workers will stay safe, and profits will be consistent. It’s a win for everyone.