Safety Tips When Using a Plasma Cutter

Metal fabrication is no joke. People in this industry must be prepared for whatever comes their way. Be ready to pour your blood, sweat, and tears into this job, although it’s best to limit the blood aspect as much as possible. After all, there’s nothing worse than being stuck on the couch for months due to a work-related injury. That’s why staff members should follow these safety tips when using a plasma cutter. You could end up becoming a couch potato who’s stuck watching soap operas all day if you don’t follow the rules.

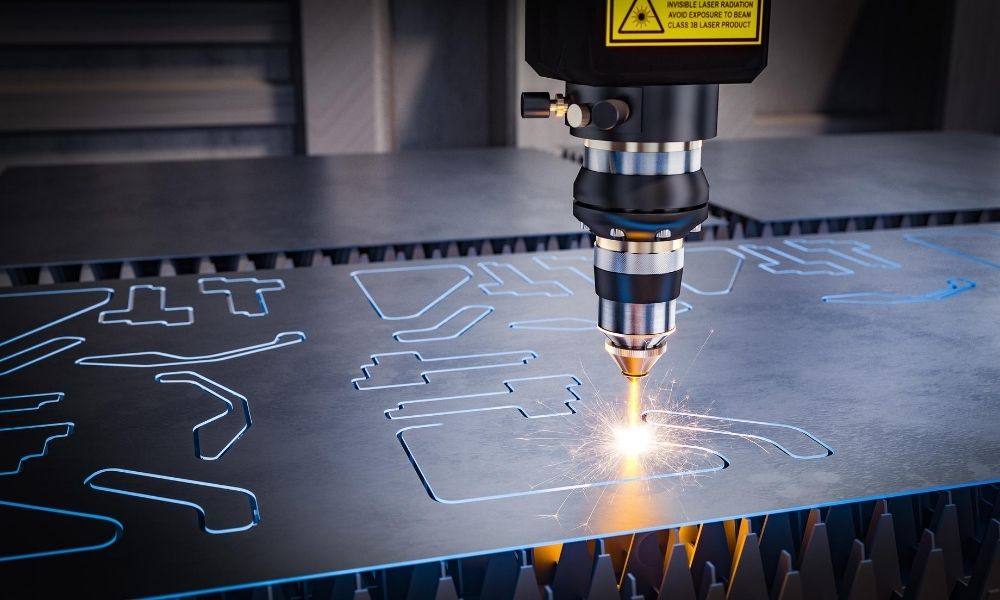

Keep the Flames at Bay

Plasma cutters are incredibly hot! You can give yourself a pretty severe burn if you get too close to the machine. That’s why it crucial for fabricators to wear flame-resistant clothing when they’re operating the equipment. No one should ever know the pain of a laser-induced burn. The intense scar that appears after the wound has healed isn’t worth the pain you’ll suffer to get it. So, every part of your skin should be covered while using a plasma cutter.

Additionally, you ought to protect your eyes. Your entire career could be ruined if a spark ends up in your eye and you can’t see what you’re doing. Consider wearing goggles and a face shield to prevent this train wreck from happening. Make sure you have nothing flammable in your pockets during operation, too. The results could be catastrophic if you’re carrying something combustible while using a plasma cutting machine.

Positioning will also keep the flames at bay. This is where training comes into play. Employers should train all their workers on proper machine usage. As a staff member, you need to know how to work the devices to prevent getting hurt on the job. For example, pointing the torch away from your body is a smart move because the closer you get, the riskier the situation. Moreover, it’s not wise to cut products that have toxic materials because they have increased flammability. Overall, it’s a supervisor’s responsibility to show everyone these things before they begin work. Company leaders can get into hot water if they don’t teach employees these safety guidelines.

Breathe In, Breathe Out

Cutting metal day in and day out is intense. You should be able to take a nice long breath in between cuts. Yet, you might be wary of doing this if the shop’s air is full of chemicals. Thus, an essential safety tip when using a plasma cutter is to place it in a well-ventilated area. Metal fabricators are inevitably going to be exposed to fumes at some point during their careers. However, this doesn’t mean that workers and their employers should ignore the problem. Keeping the devices in an area that has clean air will save endless headaches in the future. Think about removing coatings from any sheet metal before cutting as well. Some materials have toxic coatings that can enter the air once plasma cutting begins. Show your lungs a little love by removing these hazardous layers beforehand. You can relish in your hard work by taking a deep breath after the job is done. That deep breath will feel even better if you have peace of mind that the air is clean.

Risks of Electrocution

Plasma cutting machines have been associated with instances of electrocution. Most fabricators would agree this doesn’t sound like a good time. If you’re among the weary, adequately secure it to the ground before usage. Any loose cables pose a threat to workers, too. It’s also vital that operators are never wet when they come in contact with the equipment. After all, fire and water don’t mix very well. As silly as it is, make sure your hands are completely dry before using a plasma cutter. Perhaps start a buddy system where coworkers remind each other to dry their hands before operation. Fabricators must stick together. If that means telling your buddy to dry his hands when he leaves the restroom, then so be it.

Hearing

Using a plasma cutting system isn’t necessarily a peaceful experience. You can’t doze off and think about what you’re having for dinner during operation. For starters, the spacier you are, the more likely you’ll get hurt. Secondly, these machines are so loud that you can barely hear yourself think. Since this equipment is so loud, mull over the idea of protecting your ears during usage. Consider purchasing top-of-the-line earplugs that you can wear at work. You’ll be thankful you have these tools at your disposal when you’re standing so close to the device. Think about using the plugs at home, too. Fabricators who are having trouble could pop their earplugs in at night to ensure they get their beauty sleep.

Manufacturing Guidelines

Always follow the manufacturers’ guidelines when you’re using a piece of fabrication equipment. There might be more instructions in the manual that you’re not aware of. Please don’t prove your spouse right by ignoring the directions. Instead, take a look at the protocols laid out by the manufacturer every time you use the machine. There’s nothing wrong with needing a refresher before every use.

Another pro tip is to call the distributor the minute you notice any issues. Do NOT try to fix the problems yourself without talking to trained professionals first. The experts at Mac-Tech have a helpline you can call for assistance. If the person on the other end is unable to resolve the hindrances, they come out and take a look. Mac-Tech sells Grade-A plasma cutting systems to fabrication shops that want to increase productivity. Since shop efficiency is one of our main goals, we want to help resolve issues as quickly as possible. We understand that time is money, so we’ll have things up and running again in no time.

Every metal fabricator knows that plasma cutting systems are nothing to scoff at. You’ll get hurt if you’re messing around with your buddies when you should be laser-focused. These injuries can be painful, and they sideline you for months. So, unless you want to become a daytime TV fanatic, you should follow these safety precautions. Being a couch potato is no fun, and you’ll have to endure tons of pain to get a gnarly scar. The experience is definitely not worth it.