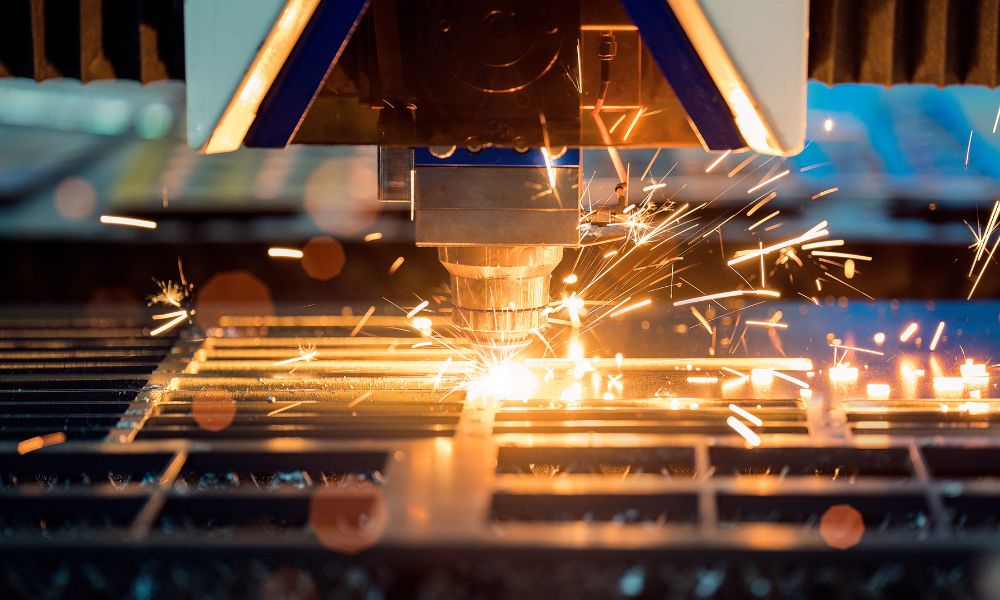

Fiber Laser Cutters vs. Plasma Cutters: 6 Key Differences

Versatility enables metal fabrication operations to take on a greater variety of work without sacrificing productivity, quality, or time. New computer-controlled metalworking equipment provides precision, speed, and flexibility, so shops can accept a wider range of work. Along with selecting press brakes and beam coping machines, most shops face a choice of fiber laser cutters vs. plasma cutters. Six key differences can help you determine if you should invest in one or the other, or both, types of machines. Evolution of [...]