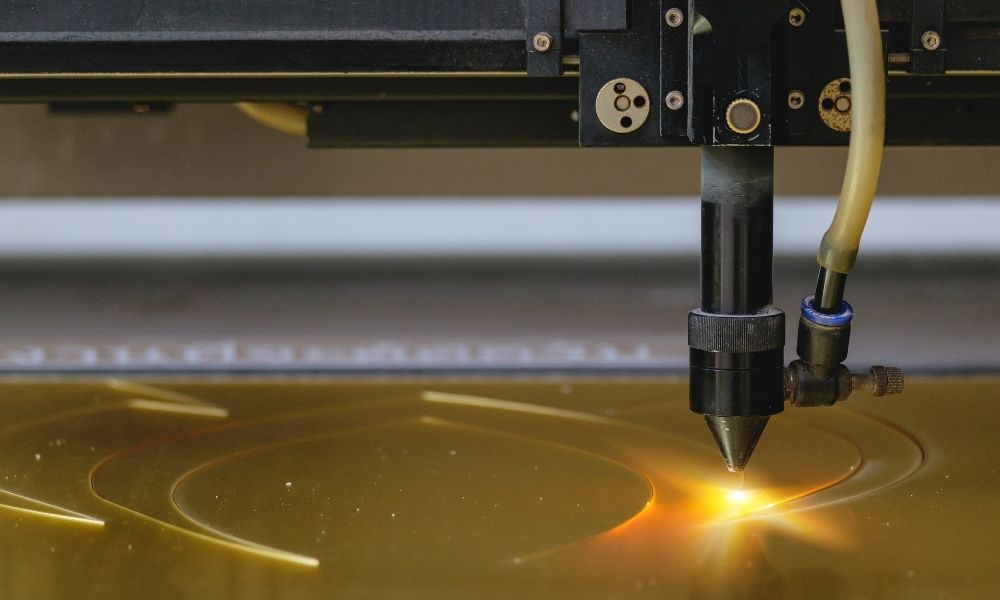

Safety Tips When Using a Fiber Laser Cutter

Fiber laser cutters are growing in popularity because they increase shop efficiency. Additionally, high-tech models are incredibly simple to use, and they make workers’ lives easier. Yet, people can still injure themselves if they don’t know what they’re doing. Here are some safety tips when using a fiber laser cutter that every fabricator should know. By following these tips, supervisors and their employees can avoid horrible workplace accidents.

Get To Know the Machine

Metalworkers can’t simply plug in a fiber laser cutter and get to work. If only it were that easy! Much to their chagrin, they must take the time to learn about every machine they use at work. For starters, individuals ought to read the manufacturer’s manual. The manual will tell staff members where to find the proper safety gears and what to do in case of an emergency.

The guidelines should also let metalworkers know what materials each device can handle. For example, it’s not wise to cut plastic with a fiber laser tube cutting machine. These tools are incredibly hot, so a fire could break out if the laser melts through the plastic. The manual might also tell people about the equipment’s thickness capabilities. No one should ever cut through a thicker material than the tool can handle because it won’t make it all the way through. Not only is this a safety hazard, but customers will not be satisfied with the finished product.

Clean the Workspace

After someone has gotten to know the machine, they must make sure their workspace is clean. Fiber lasers don’t spew dust particles because everything disintegrates from the heat. However, leaving a piece of scrap metal near the equipment could pose a fire hazard. What’s more, an explosion may occur at the metal fabrication shop. Needless to say, no one wants that. As a result, fabricators must clean the surrounding area before they begin a project. Though this may seem like a relatively small step, it could prevent significant headaches in the future.

Safety Gear Is a Must

Another step workers must take before they work with a fiber laser tube cutting machine is getting their safety gear in order. Fiber lasers are among the most dangerous pieces of equipment in a fabrication shop because the lasers reach extreme temperatures. Moreover, if a piece of scrap metal flies off the cutting area, someone can get seriously hurt. So, individuals must wear personal protective equipment to keep themselves safe.

Luckily, workers don’t need to obtain the equipment themselves. Supervisors should provide staff with durable goggles to protect their eyes. Fabricators should also wear thick gloves while operating the machinery to avoid potential burns. It’s an employer’s responsibility to give workers these products so they can prevent a lawsuit. Yes, metalworkers know the risks involved when they enter the profession, but that doesn’t mean bosses can completely ignore safety protocols in their shop. People need safety gear so the workflow can remain consistent, and everyone can reduce the likelihood of accidents.

Other Responsibilities of the Employer

Aside from giving people the proper PPE, supervisors must also develop superior training programs. These training programs should include these safety tips for using a fiber laser cutter, as well as other factors that’ll help keep people safe. For example, shop managers can appoint a laser safety officer to watch over staff members while they use the machinery. This person must be skillfully trained and ready to assist fabricators at a moment’s notice.

Additionally, employers must pay attention to where they place the fiber laser cutter in the shop. Believe it or not, machine placement is just as important as following safety protocols. If an establishment’s workflow is out of order, fabricators may trip over a wire and cause an otherwise preventable accident. Essentially, everyone at the workplace should work as a team to maintain an accident-free streak at the shop.

The Cut Itself

Once an individual completes all the necessary steps, they can finally start to cut materials. Metalworkers must first ensure that they have aligned the piece of sheet metal properly. Everything must be straight so the cuts can be as accurate as possible. Next, fabricators need to get in the zone. Operating a fiber laser tube cutting machine leaves no room for daydreaming. Staff members can’t think about what they’re going to have for dinner while they’re on the job. Instead, they must concentrate on ensuring that every angle is precise and no accidents happen.

Fabricators must also keep their hands steady while using heavy-duty devices. Gloves will help make this task a little easier, though ultimately, it’s up to the worker not to lose their cool. Supervisors may assign two people to do one task at a time so they can watch over each other while completing the job. Production will still remain steady, and this increases the likelihood that everybody will stay safe.

After the Cut

A metalworker’s job isn’t complete after they make the perfect final cut. Fabricators should check over the machine to ensure nothing is leaking out and that everything is in working order. Fiber laser cutters must have the right amount of coolant so the temperatures can drop after the machine is turned off. If anyone notices suspicious spills, they should tell shop managers immediately.

If the post-cut inspection checks out, staff members ought to clean their workspace. If they leave a scrap at their workstation, a fire could ignite. In the best-case scenario, nothing happens, and everyone’s fine. In the worst-case scenario, however, the shop burns down while no one is there. For these reasons, employees must look over every device after they complete a job.

Metal fabrication shops are always busy because they provide materials for various industries. The demand can be overwhelming at times, but this doesn’t mean that supervisors can ignore proper safety protocols in the name of productivity. Rather, managers ought to develop training programs and shouldn’t allow folks to begin working before they know what they’re doing. Establishing these programs will take some extra time and money. However, no manager can put a price on their staffs’ safety and well-being. The safer people feel at work, the more productive they will be.